|

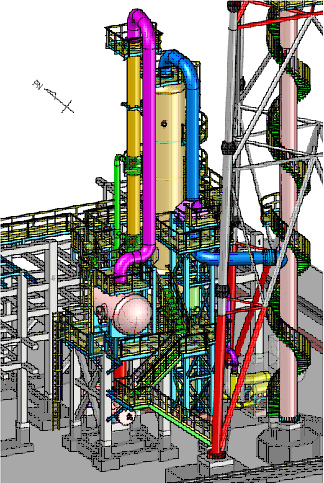

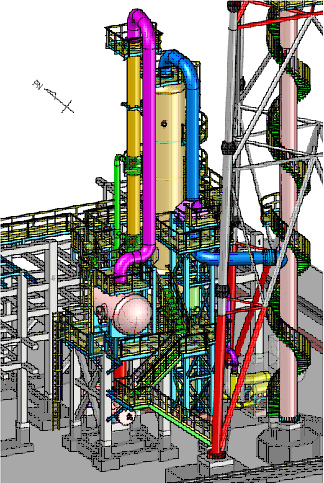

3D Diagram

(South-West View) |

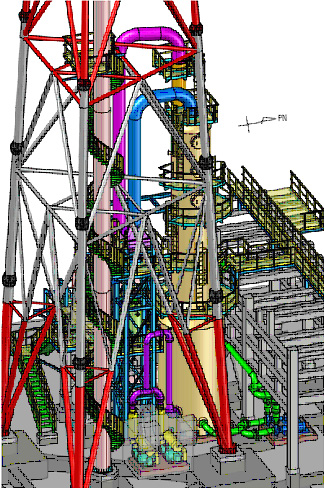

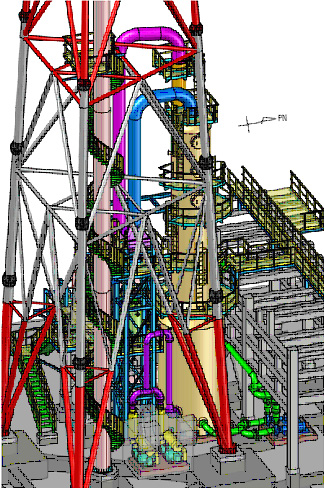

3D Diagram

(South-East View) |

Current Site Situation before Construction |

1.

Proj. Name:CPC

Talin Refinery SRU#4 Sulfur Oxide Scrubber Project

2.

Client:Talin

Refinery of CPC Corp., Taiwan

3.

Proj. Period:July

2024∼Otc.

2025

4. Proj. Description:

This project is for CPC-TL to reduce SRU #4 Tail Gas SO2

emission by adding a SO2

absorption Unit of caustic Scrubbing Facilities between the existing

Catalytic Incinerator (R-4362) and Stack (M-4363) within the very narrow &

limited available site space. Based on SRU #4 Tail Gas Inlet/Outlet Design

Baselines for the new Scrubbing Facilities, it is expected that:Capacity

in tail gas flow rate of 10,906 Nm3/h Max. w/ 1.2 Vol% SO2

concentration Inlet, and after scrubbing the outlet SO2

concentration can be

≦30

vppm, the scrubbed tail gas temp. can be re-heated up to

≧135℃

by a MS Steam Re-Heater to avoid white plume produced at Stack Exit;meanwhile,

the effluent COD

≦1,000

mg/l, PH:6~9

after scrubbing, and the effluent temp.

≦38℃

by using an Effluent Cooler are required to be met.

5. Major construction item:

◆

SO2

tail gas Scrubbing Facilities x 1 Unit (Incl. Alloy C-276/AL-6XN Inlet

Barrels, 316L Disengagement Vertical

Vessel, SiC Reverse jet Nozzles (x2),

316L Packed Section, 316L Chevron Demisters……, etc.).

◆

Oxidation Air Blower x 2 sets (Inc. Noise Hood).

◆

316L Scrubbing Circulation Pump x 2 sets, 316L Effluent Discharge Pump

x 2 sets, and LC Pump x 2 sets.

◆

316L Steam Re-Heater x 1 set, 316L Effluent Cooler x 1 set, and Steam

Separator x 1 set.

◆

30”∮SO2

tail gas

Inlet/Outlet Pipelines retrofitted (Inc. Refractory Lining)

and

new supplied Pipe Fittings, Exp. Joint, and Instruments on the

30”∮Pipelines.

◆

Process & Utility Piping System (Inc. Utility Station) w/different kinds of

Material, Effluent Wastewater Piping (Inc. 304 SS Effluent Filter).

◆

Pilings, Civil Foundation, Steel Structures, Operation Platforms, related

Acquisition of Government Permits and Construction License Application.

◆

Instruments Incl. PLC, Control Valves, Radar/Magnetic Liquid L/G & L/T,

Magnetic or D/P Flow Meters, Density Transmitters, PH Analyzers,

Thermometer/ Pressure Gauges, etc.

◆

Power Equipment Incl. MCC Panel, Site Explosion-proof Lighting Fixture,

Grounding, Power Cable and Conduit, Site Switching Station.

|

Mascol Engineering Co.,LTD

Mascol Engineering Co.,LTD![]()