|

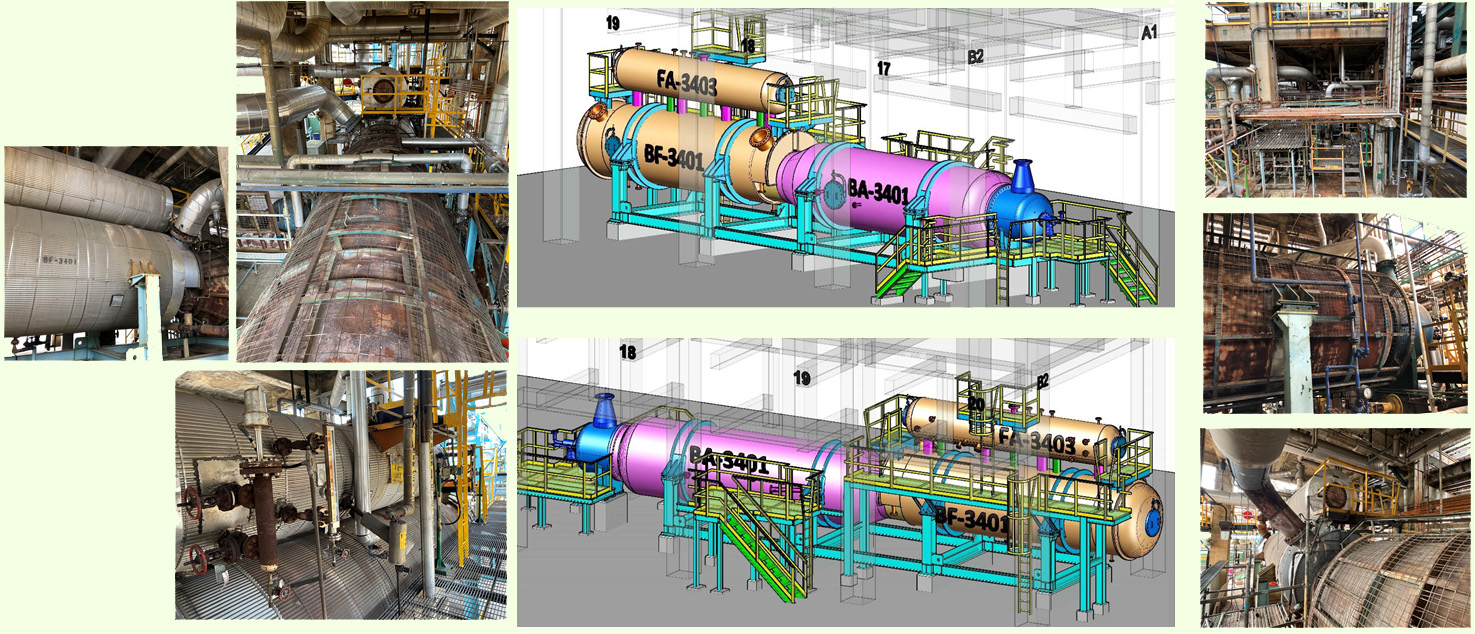

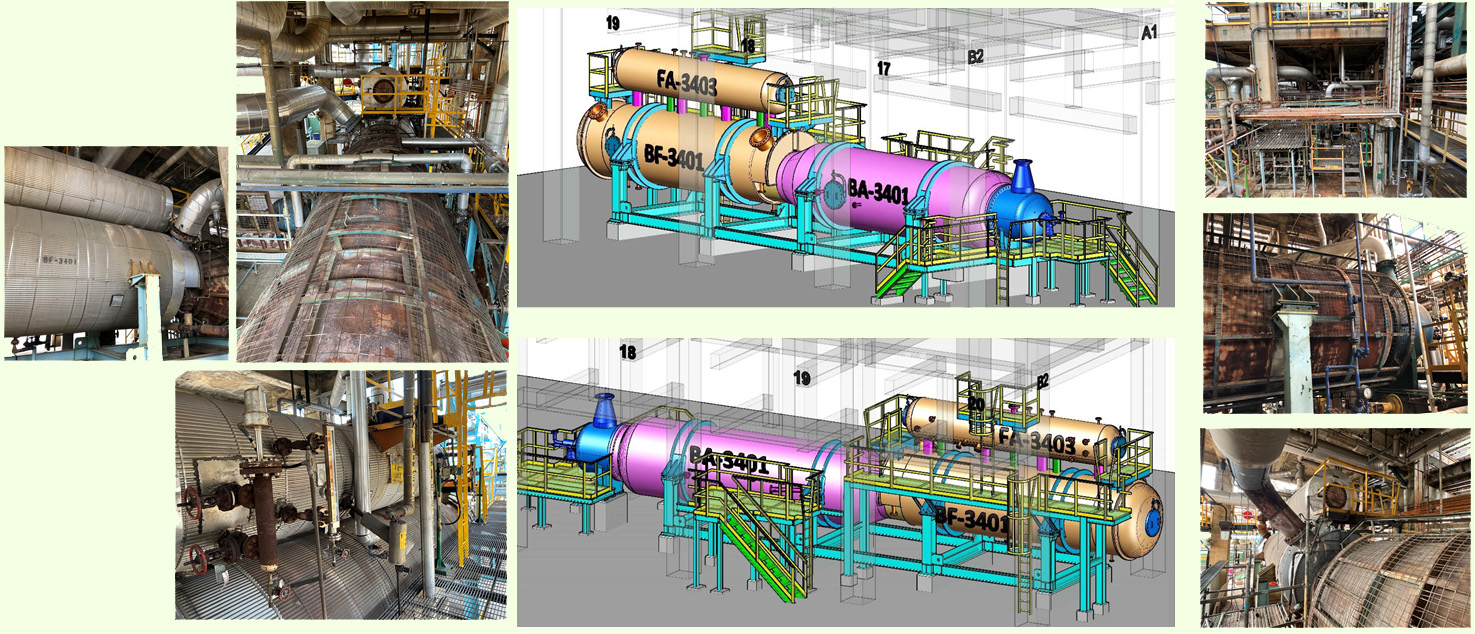

Current Site

Situation

before

Construction |

Proposed 3D Diagrams

after Replacement |

Current Site Situation before Construction |

1.

Proj. Name:CPCT

SRU#2 Muffle Furnace and Waste Heat Boiler Replacement

EPC Project

2.

Client:CPC

Tao-yuan Refinery

3.

Proj. Period:Mar.

2025∼May

2026

4. Proj. Description:

This Project is to replace CPCT SRU#2 three old exist equipment including

Muffle Furnace (BA-3401)/ Waste Heat Boiler (BF-3401)/ and Steam Drum

(FA-3403) with new ones because they have gradually become hard repaired and

out of order after being operated over forty years. In order to improve the

reaction effect of the Furnace, the hexagonal ceramic blocks "Vectorwall" is

specially selected as the Checkerwall of the Furnace in this project. It can

generate process M.P. Steam (≦20kg/cm2

G) on the shell side of the WHB to achieve the purpose of energy saving and

carbon reduction. In addition to upgrade with optimization including the

Furnace Refractory, Checkerwall, Ferrules on WHB front tube sheet and

Linings for compliance with the necessary regulations, new equipment shall

follow the original equipment outline and structure design and material

supply. A new set of AUTOCAD editable design drawings shall be drawn for

future maintenance referenced by relevant units of the Client. After being

replaced and updated, on the condition of the Furnace is operated within

1400°C, the temperature at any point on the Furnace outer wall surface shall

be

≦

300°C.

5. Major construction item:

◆

Muffle Furnace x1 Set,

2,300mm ID x 8,650mm T/T x 20tmm Mat'l

A516-70 w/

Check Wall, Refractory Lining and Dry out, Pop: 0.68kg/cm2G @Top:

1400°C(max.).

◆

Waste Heat Boiler x1 Set,

2,180mmID x 6,400mmT/T x 26tmm Mat'l

A515-70 w/Insulation,

Tube Side: Pop: 0.61kg/cm2G @Top (in/out) 1312.5/600°C

and 600/290°C,

Shell Side: Pop: 20kg/cm2G @Top: 208°C,

◆

Steam Drum x1 Set,

1,200mm ID x 6,400mm T/T x 16tmm Mat’l A515-70 w/ Insulation,

Pop: 20kg/cm2G @Top: 208°C,

◆

『Insulating

+ Refractory』Bricks

to be designed inside Furnace for thermal Insul. improved.

◆

Equipment dismantling/installation/lifting/transportation and structure

Reinforcement.

◆

Disassembly/assembly of pipelines, application for pressure vessels, alkali

cleaning,

de-hydrogen w/annealing, replacement of I/E conduits/cables, etc.

|

Mascol Engineering Co.,LTD

Mascol Engineering Co.,LTD![]()